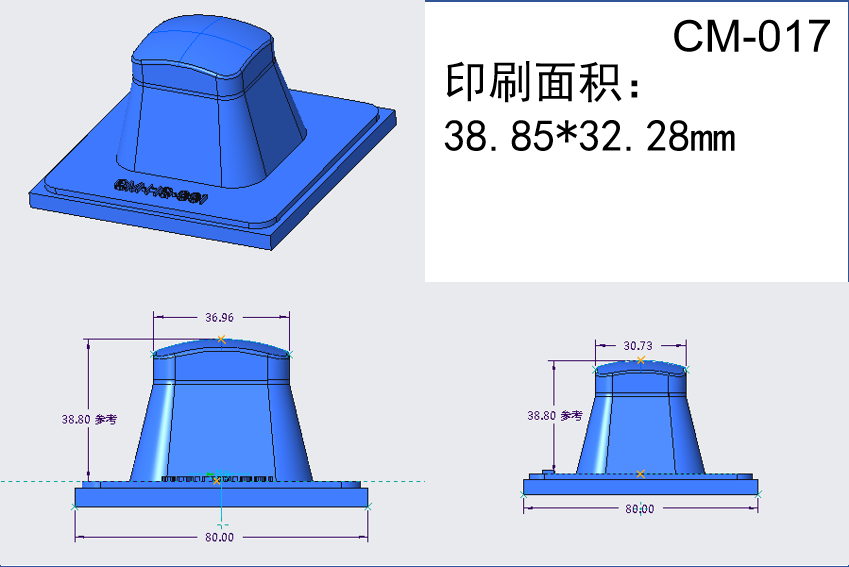

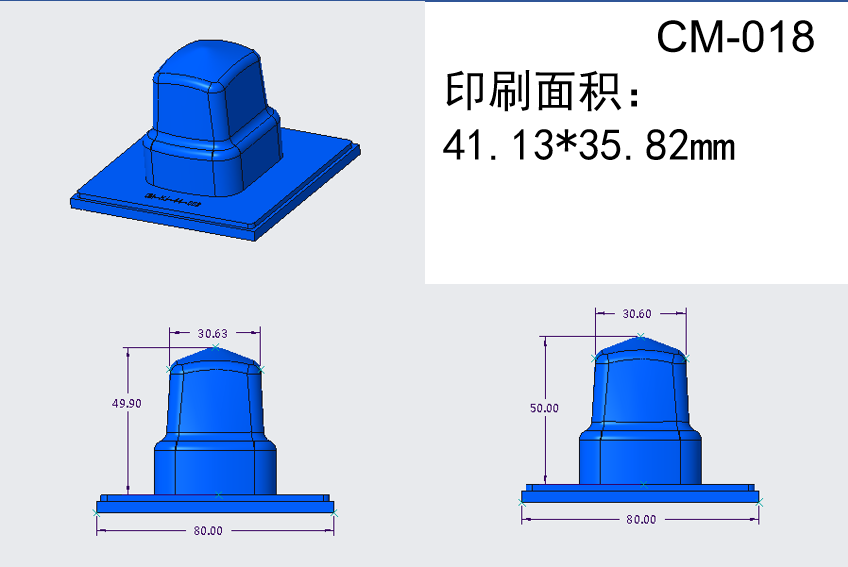

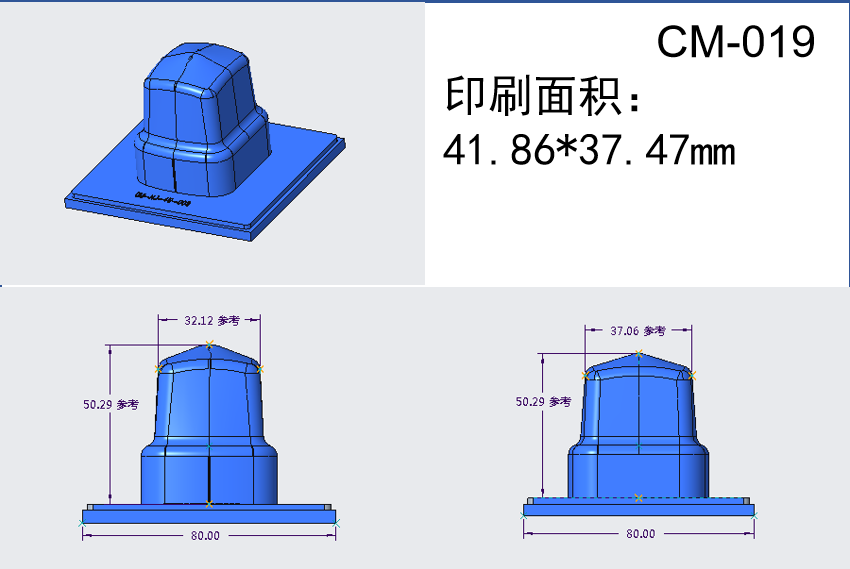

2.1 Main application scenarios: Mainly applicable to products such as four-curve watch covers and protective sheets.

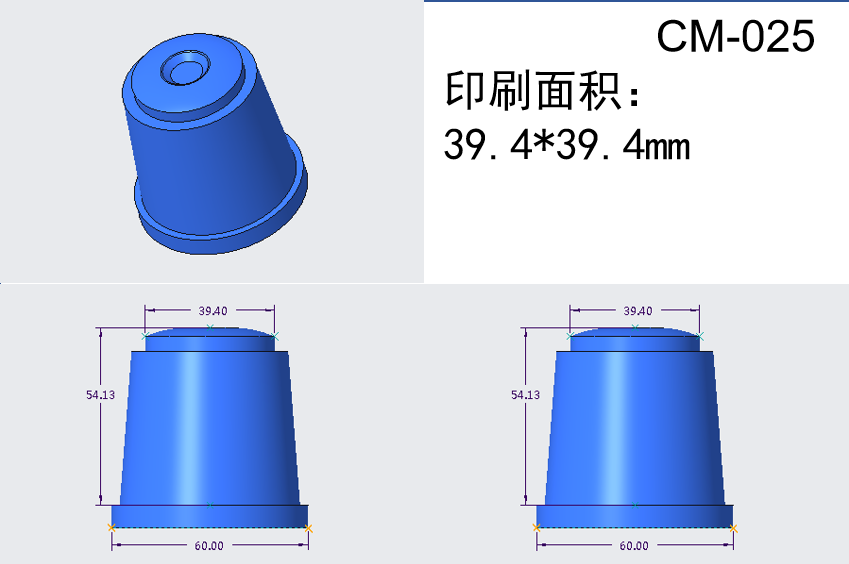

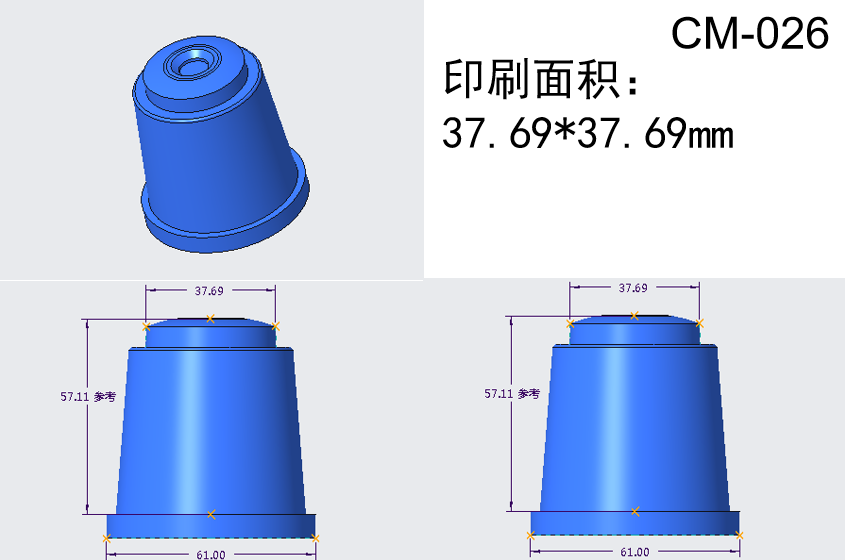

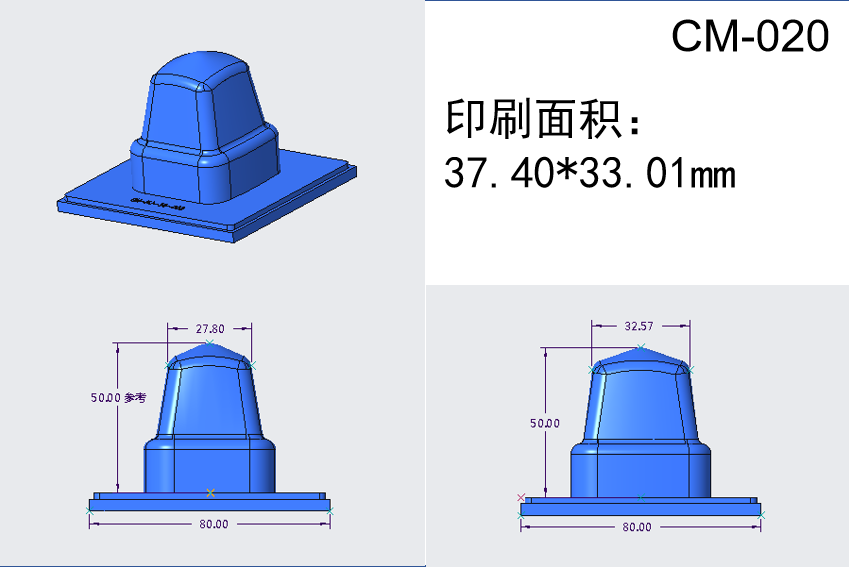

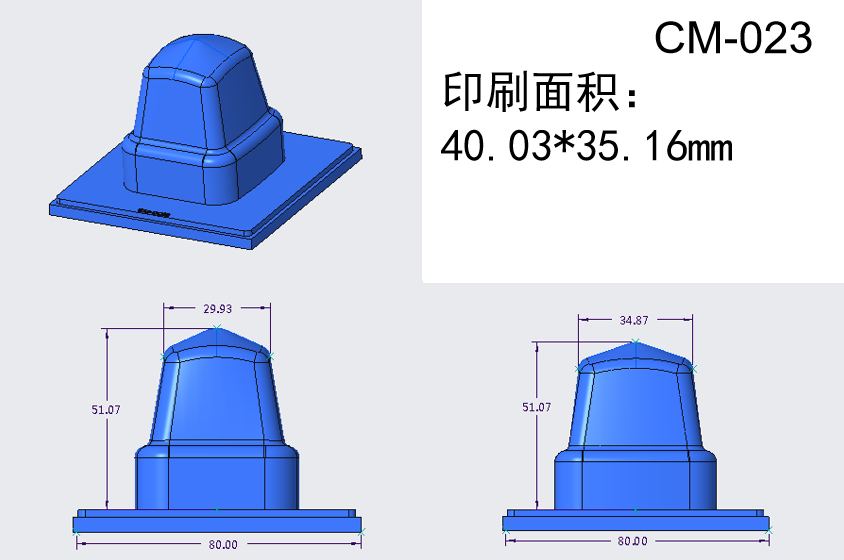

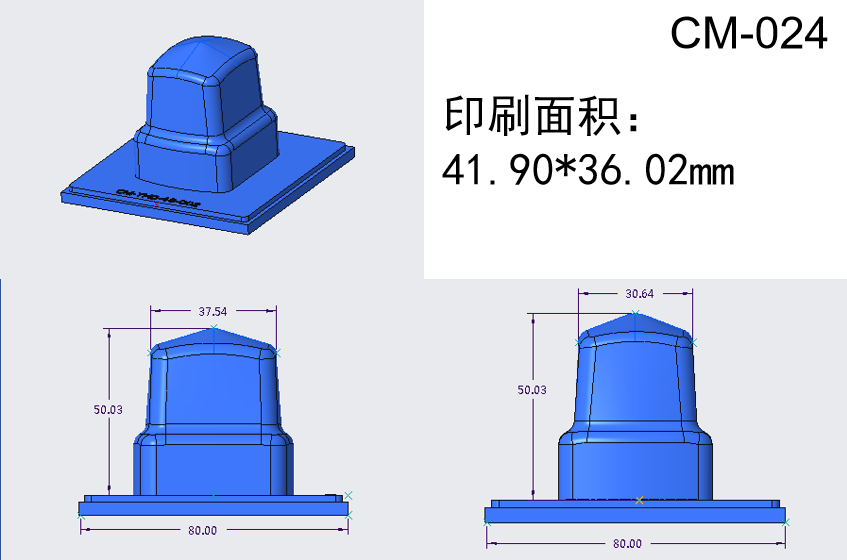

Watch covers come in a variety of shapes, so special tips need to be designed according to the specific shape of the cover, such as a cylindrical tip, so that the upper step of the cover is located in the hollow cavity of the tip body, so that the pad printing plane and the lower step of the step surface of the pad are adhered to.

Due to the special characteristics of this type of adhesive head needs to be close to the product, the adhesive head is difficult to adapt, so the adhesive head needs to be customized.

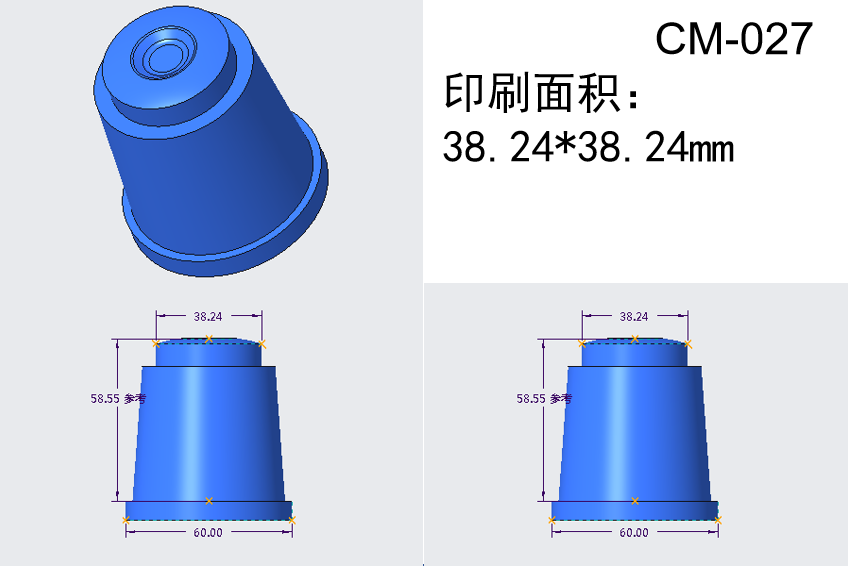

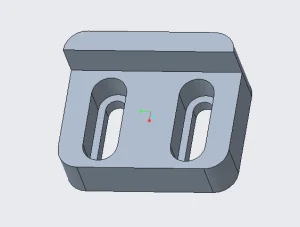

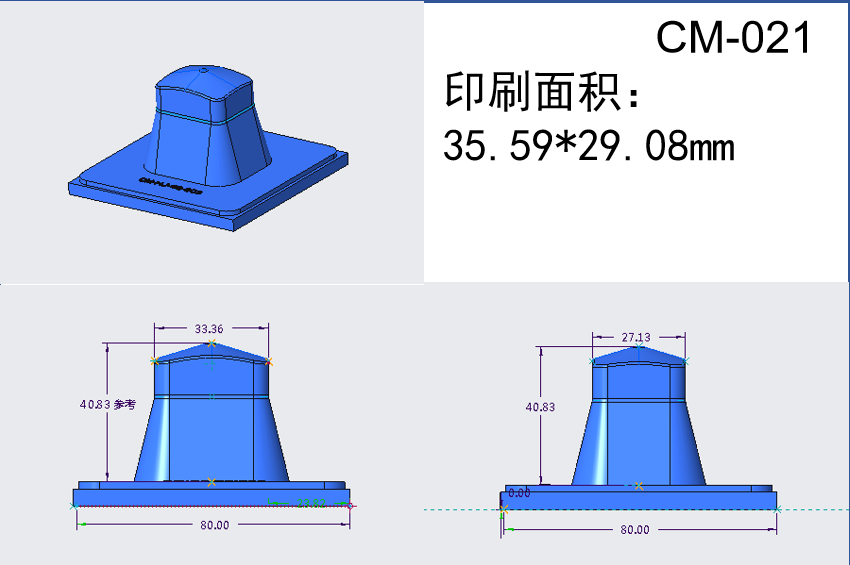

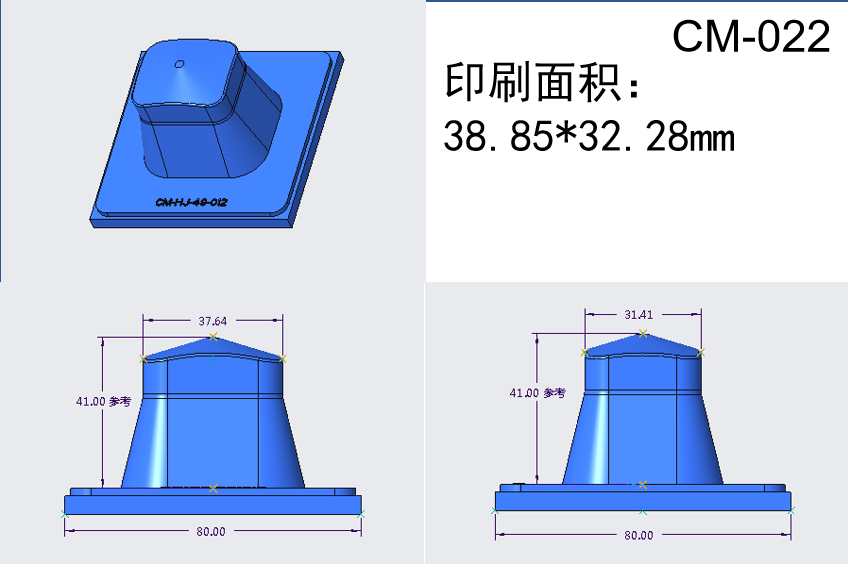

2.2 Main application scenarios: mainly applicable to watch cover groove design and other products.

Recess pad printing needs to be matched to the design of the corresponding adhesive tip, so that the adhesive tip can penetrate deep into the recess and achieve a good rolling tight fit with the bottom, side walls and other areas that need to be pad printed to ensure that the ink is transferred uniformly.

Due to the special design of this product, it is difficult to adapt the rubber head, so the rubber head needs to be customized.