3D Glass Pad Printing Technology Solution Specialist Specialized in the development and production of Silicone rubber pad and steel plates

With “standardized production”, “precision technology” and “high stability” as the core, we solve all kinds of 3D glass printing problems for our customers, and help to improve the yield and efficiency of the production line.

High Standards - High Precision - High Stability

With years of experience in the pad printing industry and a continuously improving process system, Chimu Technology has developed full-process capabilities from design and prototyping to mass production. Leveraging independent research and development, standardized production, and strict quality control, we provide customers with professional pad printing solutions that offer high stability, high yield, and sustainable mass production capabilities.

Mature Technology

After years of precipitation, the production process of Silicone rubber pad and steel plates has been standardized along the entire chain; from materials, processes to testing are all controllable and traceable, ensuring that each batch of products has a high degree of consistency in quality and stability.

Industry Cooperation

For many years, we have been deeply engaged in the field of optoelectronic manufacturing, and have maintained long-term cooperation with head enterprises such as BYD, Biel, Luxshare and Xinhao Photoelectricity Technology, etc. We have accumulated a great deal of technical experience and process optimization capability in complex projects.

Stable Delivery

Through the mature process system and strict IQC/FQC/OQC inspection process, we ensure high yield and high life time of the products to reliably satisfy the customer's demand for high volume supply and long-term stable production requirements.

Main Business

Chimu Technology is deeply engaged in pad printing and precision manufacturing, and has built up a perfect product supply system around Silicone rubber pad, steel plates, inks and customized fixtures. Relying on mature R&D capability and stable mass production process, we provide customers with diversified solutions covering printing consumables, pad printing process, silicone products and customized equipments to meet the diversified needs in different production scenarios.

Shenzhen CHI MU Technology Co.

Shenzhen CHI MU Technology Co., Ltd. is a technology-based enterprise deeply engaged in the field of pad printing and precision manufacturing, founded in 2018 and headquartered in Longgang, Shenzhen. The company is mainly engaged in the research and development, design and mass production of printing consumables, Silicone rubber pad, pad printing steel plate and other products, with the ability to develop the whole process from material, structure, process to testing.

The core members of the team come from the world's top 500 OEMs and have more than 10 years of experience in the industry, which enables us to quickly complete the process development and customization of multi-specification and multi-surface products according to customer needs. Through the integration of supply chain resources and strict IQC / FQC / OQC quality system, we provide customers with professional pad printing solutions with high stability and yield in complex processing scenarios, such as curved glass, photovoltaic modules and electronic components.

At present, the company has maintained long-term cooperation with leading enterprises in the industry, such as BYD, Biel, Luxshare and Xinhao Photoelectricity Technology, etc., and has gradually become a leading solution provider in the field of 3D glass printing by virtue of the breakthrough technology of the four-side warped glass pad printing process.

Business Partners

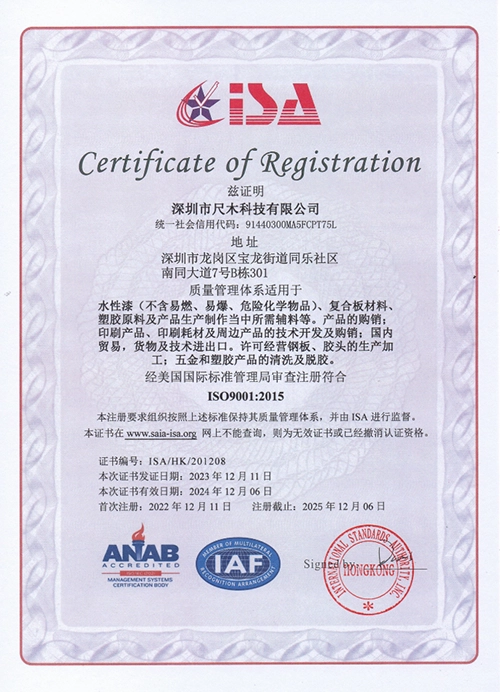

International Standard Certification, More Trustworthy Quality

Our company has passed the ISO quality management system certification, and each step of the process, from project design, material selection to manufacturing and final inspection, strictly follows the international standards. Our systematic management ensures the stable performance of our products and provides our customers with higher quality and longer service life of our Silicone rubber pad and steel plates.

Strict Process Standardization

All processes are carried out in accordance with ISO requirements for standardized and traceable production management.

Total Quality Control

Establish IQC, IPQC, FQC, OQC full-process quality inspection system, multi-dimensional control of product quality.

Double Guarantee of Materials and Workmanship

From raw material inspection to process optimization, layers of calibration ensure that product life and stability reach the industry benchmark.

Continuous Improvement Mechanisms

Continuous improvement of production efficiency and product consistency through data monitoring, process optimization and regular audits.

News & Events

Contact

- Landline: 0755-28683275

- Cell phone: 189-0244-8307

- E-mail: pmc@szcmtech.com

- E-mail: john.wang@szcmtech.com

- Address: 301, Building B, No. 7, Nantong Avenue, Tongle Community, Baolong Street, Longgang District, Shenzhen, China