Research and Development Innovation

R&D Innovation - Driving Industry Upgrade with Technology

Chimu Technology takes independent R&D, precision manufacturing and standardized process as the core driving force, and continuously optimizes the material system, structural design and production process of the Silicone rubber pad, pad printing steel plates and related consumables, in order to provide customers with pad printing solutions with higher stability, longer lifespan and higher yield.

Continuous innovation to break through the boundaries of pad printing technology

Through material modification, structure optimization and process innovation, we continue to improve pad printing suitability and finished product performance.

Customize the most suitable process solution for the customer

Rapid customization for special projects based on different glass structures, warpage, dimensions and application scenarios.

Dual engine drive of standardization and digitization

Ensure mass production stability with R&D data, process standardization, and equipment visualization.

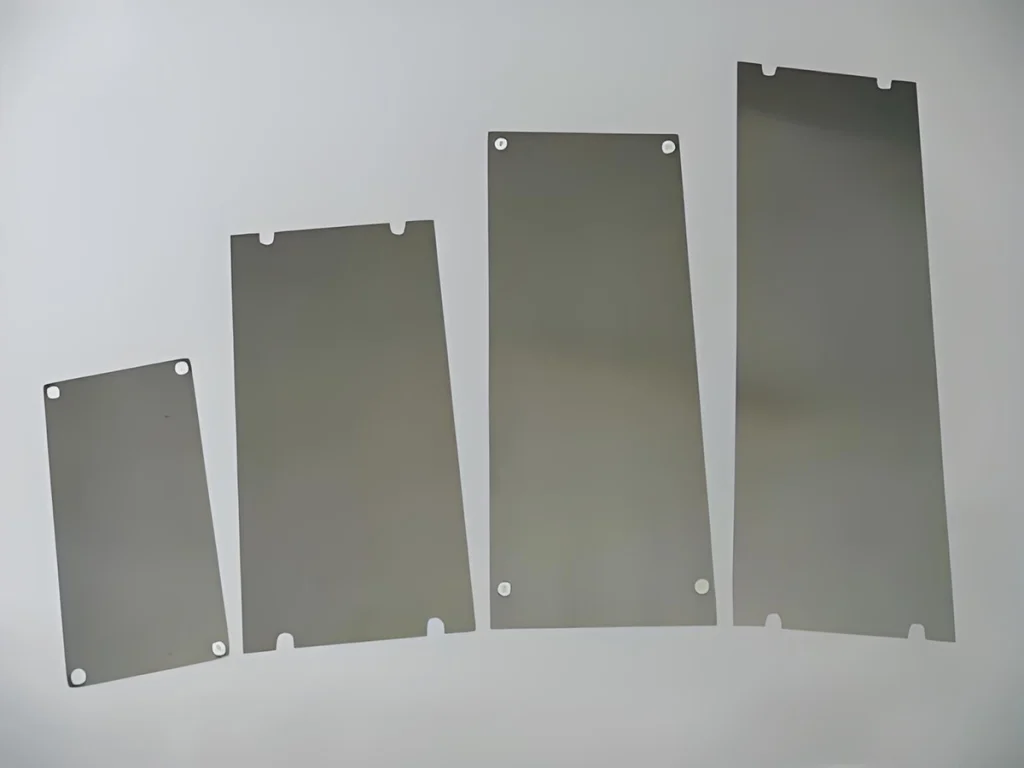

Technology development of Silicone rubber pad

Through the optimization of material formula, iteration of mold design, vacuum defoaming and high temperature curing and other process innovations, we have made the adhesive tip with better ink absorption, release and durability, which is able to adapt to the complex structure of straight side, 2.5D, 3D four-side warping, etc., and achieve clearer and more stable printing effect.

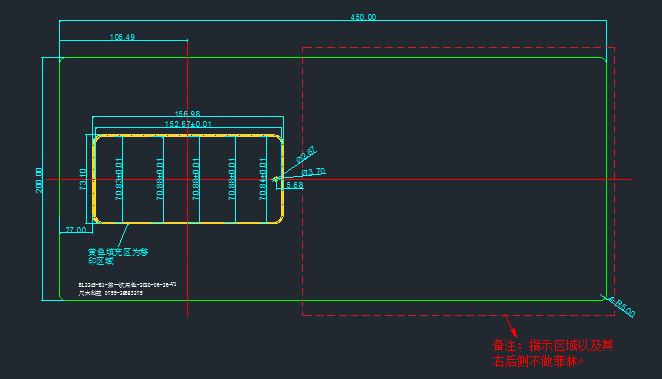

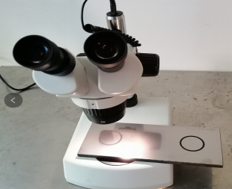

R&D capability of pad printing steel plate (etching steel plate)

We have independently constructed a standard system for steel plate etching, which realizes high-precision steel plates with uniform line width, depth, and texture by means of a highly stable exposure source, uniform adhesive application technology, and precise etching control. Consistency and long life are maintained regardless of curved surface printing or deep grain structure.

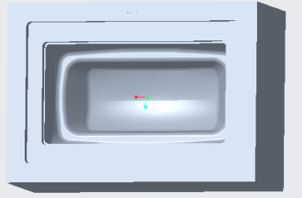

Development of solutions for complex structural parts (four-sided warped glass)

In response to the industry's problem of the four-side warping structure of 3D glass for cell phones, we have formed a set of mature and mass-producible solutions through the design of the head structure zoning, pressure balance, special etching steel plate and optimization of process parameters, which have been successfully applied in the projects of many head brands.

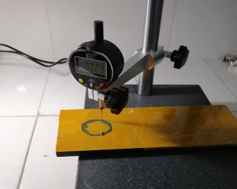

Silicone rubber pad Development and Production Process

set design

Clean Steel Plate

Photopolymer

exposure (e.g. of photosensitive material)

expose (a photographic plate)

chemical etching

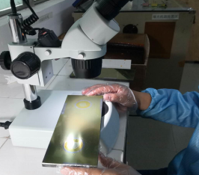

Inspection of shipments

Etched Steel Plate R&D and Manufacturing Process

Glue head and mold design

Raw materials for making rubber tips

agitation

vacuum

Mesh filtration

roasting

Inspection Packaging