Company Profile

Shenzhen CHI MU Technology Co.

Shenzhen CHI MU Technology Co., Ltd. is a technology-based enterprise deeply engaged in the field of pad printing and precision manufacturing, founded in 2018 and headquartered in Longgang, Shenzhen. The company is mainly engaged in the research and development, design and mass production of printing consumables, Silicone rubber pad, pad printing steel plate and other products, with the ability to develop the whole process from material, structure, process to testing.

The core members of the team come from the world's top 500 OEMs and have more than 10 years of experience in the industry, which enables us to quickly complete the process development and customization of multi-specification and multi-surface products according to customer needs. Through the integration of supply chain resources and strict IQC / FQC / OQC quality system, we provide customers with professional pad printing solutions with high stability and yield in complex processing scenarios, such as curved glass, photovoltaic modules and electronic components.

At present, the company has maintained long-term cooperation with leading enterprises in the industry, such as BYD, Biel, Luxshare and Xinhao Photoelectricity Technology, etc., and has gradually become a leading solution provider in the field of 3D glass printing by virtue of the breakthrough technology of the four-side warped glass pad printing process.

Business Partners

Industry-leading pad printing total solution provider

Specializing in curved glass, optoelectronic display, and precision manufacturing, we provide customers with high stability adhesive tips and high precision etched steel plates.

Technology-based company specializing in 3D glass pad printing

With more than ten years of experience in process research and development, we have successfully solved industry challenges such as four-side warpage and deep curvature glass.

Reliable partner serving multiple head manufacturing companies

Long-term cooperation with well-known enterprises such as BYD, Bourn Optical, Xinhao Optoelectronics, Ophthalmics, etc. Stable support for large-scale mass production projects.

Why do we stay ahead in the pad printing industry?

Chimu Technology has been focusing on the R&D and production of Silicone rubber pad, etched steel plates and related consumables for a long time. With mature standardized process system, core technology precipitation and strong customization ability, we have successfully supported many types of printing projects with complex structures. Over the years, we have maintained in-depth cooperation with industry benchmark companies such as BYD, Biel, Luxshare and Xinhao Photoelectricity Technology, and Jingzhuo Optical Display, and have undertaken process development and mass production support for a variety of curved glass, 3D structural components and other high-difficulty projects.

With the core concept of “Precision Manufacturing, Stable Quality”, we help our customers to improve mass production yield and shorten delivery cycle by continuously optimizing processes, equipment and testing procedures, and continuously promote the upgrading of the industry's printing standards.

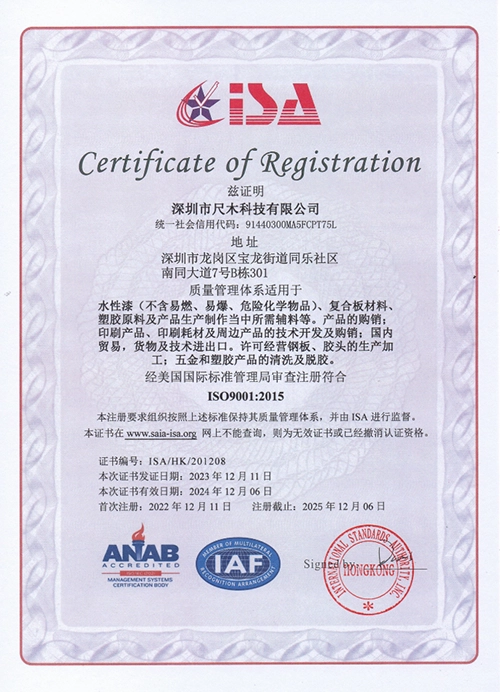

Honors and Qualifications

Ruling on the continuous investment in R&D of pad printing process, Silicone rubber pad and steel plates, Chimu Technology has obtained a number of national and industry certifications. Our technological achievements and innovation capabilities have been recognized by authoritative institutions and partners, and the relevant invention patents, utility model patents and high-tech enterprise certification fully demonstrates the company's strength and leading position in the field of precision manufacturing.

Corporate Vision

We are committed to becoming a reliable international technology company in the pad printing process field.

Relying on the continuous innovation of pad printing technology and high standard quality system, we provide more efficient and stable printing solutions for the global optoelectronic and precision manufacturing industries, and promote the industry to achieve higher quality development.

Core values

Simple, pragmatic and efficient

Openness, introspection and integrity